In 2016 I attended Autodesk University and took from it that AR & VR were the hot topics. I participated in classes on one click from REVIT to VR, HoloLens was featured in classes and displays showing it’s ability to display the model instead of looking at a drawing. Booths like Prospect by IrisVR were showing off room scale model viewing. It seemed like a dawn of a new era for visualization.

It is now 6 years later, and while the space is growing, there seems to be an anchor on adoption. I have a background in piping and was immediately enthusiastic about this new technology. Therefore, once I returned to my office, we acquired a headset. Iris VR was the clear leader at the time, in my opinion, and we utilized the technology to give our team a jump on information. I currently still use Iris and a HTC VIVE Pro to convey models in various forms. I also feel that FARO Technologies’s point cloud viewer in Scene is a solid runner up for my software stack and aiding visualization to the team.

Demand for VR has been increasing globally over the years but has not yet taken off in an expansive way. The main culprit, in my opinion, is that most people do not know the full scope of uses, and therefore cannot see the ROI. The second factor is most likely a technology block, or in other words, how do we even get this thing to work once we have it?

What I think the best use cases for VR in the piping industry are as follows:

1. Initial model review / walkthrough of design intent

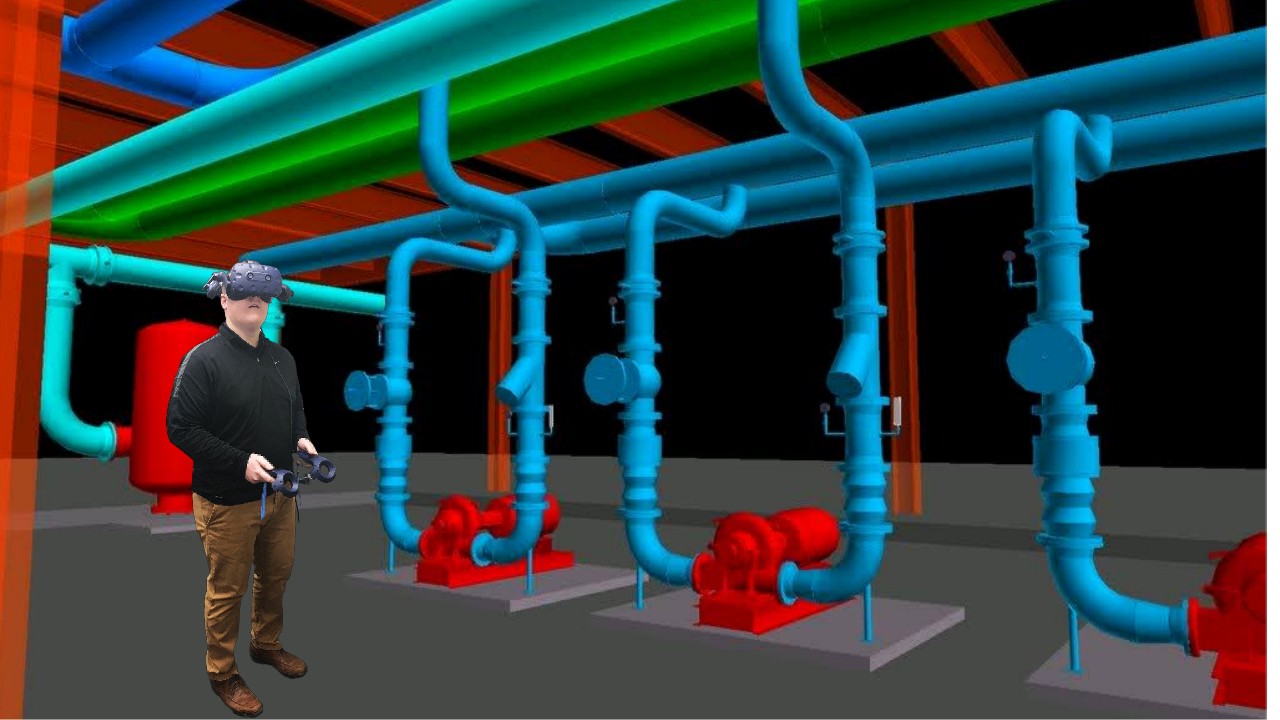

When you receive a model for a project and want to inspect it you can certainly review the PDF’s and look through the model in REVIT or Navisworks. You can also take it a step further and walk the project. I wonder how many engineers would rework designs if they used this method for review? Even a quick walkthrough gets you up to speed on overall layout and locations much faster as you are immersed in the project and can get to navigate through the actual design.

2. Review initial layout of detailers

Once a detailed model is generated by one of our United Association detailers, we usually walk the space. Here you can see quickly if something is constructible and operable or not. I’ve seen many times what I like to call “top down syndrome” where in a flat drawing something like a valve looks accessible, but standing at 1:1 scale it’s above an object, or unreachable from the floor / ladder. Piping layouts can be intricate and having the ability to walk the space generally helps in the constructability area immensely.

3. Foreman walkthrough ( first day on the job)

When a foreman is selected for a project and if the project is new construction, the job could be a dirt hole at the time they start. A VR walkthrough of the architecture, along with the draft of the piping layouts, will generally get someone up to speed faster than looking at flat drawings for design intent. Generally, the initial walkthrough starts outside the building as an overview. Then, access areas, crane pick areas, laydown etc. can be established before they set boots on the ground. This way when they get to the job site they have a working knowledge of the intent and are able to orient themselves faster than from being handed a roll of drawings and specs and a pat on the back!

4. Foreman review mechanical rooms prior to fabrication

When detailers are at the point of final coordination, it’s a great time to bring in the person who will be heading up the installation portion of things. Means and methods can play a huge part of the overall design and subsequent installation. Having the field and office on the same page will not only speed up the process, it also gets everyone on the same page! Items like supports, tap locations, layout of equipment and even selection of fittings / types of flanges take place at this point. The foreman now has a working knowledge of the space, and how it will be assembled. The cost is something to consider as it is much cheaper, safer and easier to change at this point digitally before fabrication is delivered to a job site.

5. Execution of fabrication / breakup of spools / logistics

When fabrication is about to take place, the time is right to walk the space and determine logistics. Where do you want your field welds? What do you want fabbed first? Mains, set equipment, branches make up a typical workflow for a mechanical room. These can be broken up in packages. VR allows one to review the field welds, see the fab packs installed (mains only for example) and make sure there is a working knowledge of the situation as it unfolds during the installation phase. Seeing the spools at a 1:1 gives a great awareness of logistics.

6. Client / engineer review of potential changes / ROM / RFI’s

Giving the client the ability to walk a space before it is constructed is an absolute home run! This is usually reserved for issues, but is a great tool for review, and even spotting potential changes that would otherwise be discovered at the end of a project, or punchlist. RFI’s and deciding if a layout works is best handled in a virtual environment. It’s not piping specific, but how can you tell if the signage in a building is visible on plans? (you can’t ) but you can see if something is blocking it in VR! The ability to show extra work needed to complete a project is also easily documented in VR. The ability to change safely, effectively, and efficiently is a dominant force in this stage.

7. Facilities review of layout prior to fabrication

Bringing facilities into the loop earlier is always a good idea. Having them walk a potential space will immediately show their concerns. The way they look at a room compared to an engineer or detailer are completely different. Can they read all the gauges? Can they access the valves? Is there adequate clearance for issues they are currently dealing with? All of these issues usually get dealt with after installation or not at all. Having input at this stage is a much cheaper way to address them. Let’s not forget that the overall experience of having a well laid out room can make an end users experience much more enjoyable. This will be great for any potential additions in the future.

8. Safety training / Virtual MOP’s

First day on the job? Need to do a Method of Procedure or any step-by-step procedure based work? A virtual walkthrough or dry run of the steps will guarantee any failures or shortcomings are caught in the VR stage and not on live equipment. Having a team familiar with the surroundings before they step foot in the space is an advantage that should never be overlooked.

9. Accessibility at any time

We haven’t talked about laser scans much, but one big use case for VR laser scans is the ability to tour a space as much as you want. Why would this even be a concern? If the space is a high security, pharmaceutical, data center, or hospital you generally can only access certain places off hours, with limited people and not disturb too much. Laser scanning the space and walking it in VR allows you to have access whenever, wherever and with whomever you want! The savings in overtime alone can be staggering, as you don’t have to pay people a premium to review a space, let alone multiple times.

10. Mockups

Lastly any mockup can be conducted virtually. With a VR environment you can make changes quickly and on the spot. The transition away from physically building mockups to a virtual one saves everyone time and money. The ordering of single pieces of equipment and the labor to create these only to be disassembled and potentially reworked creates an advantage in VR all by itself.

If you made it this far, thank you! There are endless possibilities for VR in the construction environment. Coming from a piping background, these are my favorite use cases. Please don’t hesitate to let me know your favorites!